Tianfei High-tech has been on the motorized ball valve factory for 25 years tf.co@tfjt.com whatsapp:+86 18920338351

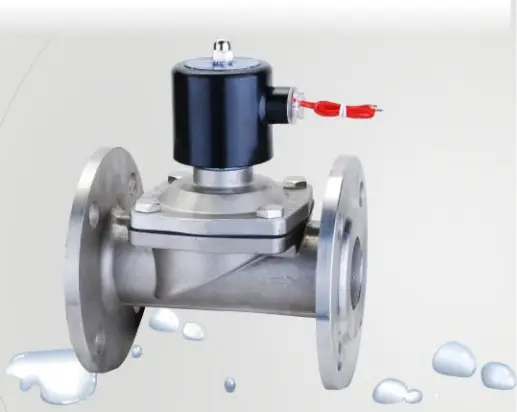

Understanding The Function Of Diaphragm Type Solenoid Valves

Welcome to our in-depth exploration of diaphragm type solenoid valves. If you've ever wondered about the inner workings of these crucial components in fluid control systems, you're in the right place. In this article, we'll dissect the function of diaphragm type solenoid valves to help you better understand their role in various applications. Whether you're a seasoned engineer or just someone with a curious mind, we invite you to delve into the fascinating world of diaphragm type solenoid valves with us.

- Introduction to Diaphragm Type Solenoid Valves

to Diaphragm Type Solenoid Valves

Diaphragm type solenoid valves are a crucial component in many industrial applications, controlling the flow of liquids and gases with precision and reliability. In this article, we will delve into the inner workings of these essential devices, exploring their function, design, and application in various industries.

At Tianfei High-Tech, we understand the importance of diaphragm type solenoid valves in modern engineering and manufacturing processes. Our team of expert engineers and technicians are dedicated to developing advanced solenoid valve technology, ensuring optimal performance and efficiency in a wide range of applications.

Function of Diaphragm Type Solenoid Valves

Diaphragm type solenoid valves operate using the principles of electromagnetism, converting electrical energy into mechanical force to control the flow of fluids. The key component of these valves is the diaphragm, a flexible membrane that responds to changes in pressure and electrical signals to open or close the valve.

When an electrical current is applied to the solenoid coil, it generates a magnetic field that attracts the plunger, causing it to move and open the valve. This allows the flow of fluid through the valve. Conversely, when the electrical current is removed, the magnetic field dissipates, and the spring within the valve returns the plunger to its original position, closing the valve and stopping the flow of fluid.

The design of the diaphragm type solenoid valve ensures a reliable and precise response to electrical signals, making it ideal for applications requiring fast and accurate fluid control. This functionality is essential in industries such as medical and analytical equipment, food and beverage processing, automotive and aerospace manufacturing, and numerous other fields where precise fluid control is paramount.

Applications of Diaphragm Type Solenoid Valves

Diaphragm type solenoid valves are widely used in a variety of industries due to their versatility and reliability. At Tianfei High-Tech, our solenoid valves are employed in applications ranging from medical devices and laboratory equipment to industrial automation and HVAC systems.

In medical and analytical equipment, diaphragm type solenoid valves play a critical role in controlling the flow of gases and liquids, ensuring precise dosing and accurate measurements in diagnostic and therapeutic procedures. In food and beverage processing, these valves are utilized for dispensing and regulating the flow of ingredients and additives, maintaining the quality and consistency of the final products. In automotive and aerospace manufacturing, solenoid valves are integral to the operation of hydraulic and pneumatic systems, providing control and safety in various processes.

Tianfei High-Tech

As a leading manufacturer of solenoid valves, Tianfei High-Tech has been at the forefront of developing innovative solutions for fluid control and automation. Our diaphragm type solenoid valves are engineered to meet the highest standards of performance, reliability, and durability, making them a trusted choice for a wide range of industries worldwide.

In conclusion, diaphragm type solenoid valves are essential components in numerous industrial applications, providing precise and reliable control of fluids. At Tianfei High-Tech, we are committed to advancing solenoid valve technology, offering tailored solutions to meet the evolving needs of our customers. Whether it's medical, food and beverage, automotive, or any other industry, our diaphragm type solenoid valves are designed to deliver peak performance and ensure the smooth operation of various systems and processes.

- How Diaphragm Type Solenoid Valves Work

Solenoid valves are an essential component in many industrial and commercial applications. They are used to control the flow of liquids and gases in a wide range of processes, from manufacturing to transportation and beyond. One specific type of solenoid valve that is commonly used is the diaphragm type solenoid valve. In this article, we will explore how diaphragm type solenoid valves work, and why they are an important choice for many industries.

At Tianfei High-Tech, we specialize in the production and distribution of high-quality diaphragm type solenoid valves. Our valves are designed to provide reliable and precise control over the flow of fluids, making them an ideal choice for a wide range of applications. Understanding how these valves work is crucial for anyone working in industries where fluid control is essential.

Diaphragm type solenoid valves are so named because of the diaphragm that separates the valve's inlet and outlet ports. This diaphragm is the key component in the valve's operation, as it is moved by the electromagnetic force generated by the solenoid. When an electrical current is applied to the solenoid, it creates a magnetic field that causes the diaphragm to move, opening or closing the valve and allowing or obstructing the flow of fluid.

The operation of a diaphragm type solenoid valve can be broken down into several key steps. When the solenoid is not energized, the diaphragm is held in place by a spring, blocking the flow of fluid through the valve. When an electrical current is applied to the solenoid, the magnetic field generated causes the diaphragm to move against the force of the spring, opening the valve and allowing fluid to flow through.

The precise control of the valve's operation is achieved by varying the strength of the electrical current applied to the solenoid. By adjusting the current, the magnetic field can be manipulated, allowing for fine-tuned control over the movement of the diaphragm and therefore the flow of fluid. This level of control makes diaphragm type solenoid valves an ideal choice for applications where precise regulation of fluid flow is required.

One of the key advantages of diaphragm type solenoid valves is their ability to provide a tight seal when closed, preventing any leakage of fluid. This is particularly important in applications where the fluid being controlled is hazardous or corrosive. The diaphragm effectively isolates the fluid from the surrounding environment, ensuring that it remains contained and under control at all times.

At Tianfei High-Tech, we take pride in the quality and performance of our diaphragm type solenoid valves. We understand the importance of reliable and precise fluid control in a wide range of industries, and we are committed to providing valves that meet and exceed the expectations of our customers.

In conclusion, diaphragm type solenoid valves are a crucial component in many industrial and commercial applications, providing precise control over the flow of fluids. Understanding how these valves work is essential for anyone working in industries where fluid control is paramount. At Tianfei High-Tech, we are proud to offer high-quality diaphragm type solenoid valves that meet the needs of our customers.

- Applications of Diaphragm Type Solenoid Valves

Diaphragm Type Solenoid Valves are an essential component in various industrial and commercial applications. These valves are widely used in industries such as water treatment, chemical processing, pharmaceuticals, and food and beverage production. Understanding the function and applications of diaphragm type solenoid valves is crucial for engineers and technicians in these industries.

At Tianfei High-Tech, we specialize in manufacturing high-quality diaphragm type solenoid valves that are designed to meet the specific needs of different industries. Our valves are known for their reliability, durability, and precision, making them an ideal choice for critical applications.

In this article, we will explore the functions and applications of diaphragm type solenoid valves, and how they can benefit various industries.

Function of Diaphragm Type Solenoid Valves

Diaphragm type solenoid valves operate using the principles of electromagnetic force. When an electrical current is applied to the solenoid coil, it generates a magnetic field that pulls the plunger or armature towards the coil. This movement opens or closes the valve, allowing the flow of fluid or gas through the system.

The diaphragm in these valves plays a critical role in controlling the flow of media. The diaphragm is a flexible membrane that separates the fluid or gas from the solenoid coil. When the valve is energized, the plunger moves and lifts the diaphragm, allowing the media to flow through the valve. When the valve is de-energized, the diaphragm closes the valve, preventing the flow of media.

Applications of Diaphragm Type Solenoid Valves

Tianfei High-Tech diaphragm type solenoid valves are used in a wide range of applications due to their versatility and reliability. Some of the common applications include:

1. Water Treatment: Our diaphragm type solenoid valves are extensively used in water treatment plants for controlling the flow of water, chemicals, and other media. These valves play a crucial role in regulating the flow of water in filtration, reverse osmosis, and purification systems.

2. Chemical Processing: In chemical processing plants, our valves are used to control the flow of various chemicals and solvents. The precise control offered by our valves ensures the safe and efficient handling of corrosive and hazardous chemicals.

3. Pharmaceuticals: Diaphragm type solenoid valves are vital in pharmaceutical production for regulating the flow of pharmaceutical ingredients and formulations. These valves are designed to meet the stringent requirements of pharmaceutical manufacturing processes.

4. Food and Beverage: Our valves are also used in food and beverage production for controlling the flow of liquids and gases. They are designed to meet the hygienic standards and requirements of the food and beverage industry.

In addition to these applications, Tianfei High-Tech diaphragm type solenoid valves are also used in automotive, HVAC, and other industrial applications.

In conclusion, diaphragm type solenoid valves are an integral part of various industrial processes, and at Tianfei High-Tech, we are committed to providing high-quality valves that meet the specific needs of our customers. With their reliability and precision, our valves are trusted by industries worldwide for their critical applications.

- Advantages and Disadvantages of Diaphragm Type Solenoid Valves

Understanding the Function of Diaphragm Type Solenoid Valves - Advantages and Disadvantages

Diaphragm type solenoid valves are an integral part of many automated systems, controlling the flow of liquids and gases with precision and efficiency. These valves consist of a diaphragm that is lifted or lowered by the application of an electromagnetic field, allowing for the regulation of fluid flow. In this article, we will explore the advantages and disadvantages of diaphragm type solenoid valves, providing valuable insight into their use and application in various industries.

Advantages of Diaphragm Type Solenoid Valves

1. Precise Control: Diaphragm type solenoid valves offer precise control over the flow of fluids, allowing for accurate regulation and adjustment. This level of control is essential in applications where precise fluid management is necessary, such as in medical and laboratory settings.

2. Versatility: These valves are available in a wide range of sizes and configurations, making them suitable for a variety of applications. From small-scale operations to large industrial processes, diaphragm type solenoid valves can be tailored to meet specific requirements.

3. Reliability: When properly maintained, diaphragm type solenoid valves are known for their reliability and longevity. This makes them a cost-effective solution for fluid control, as they require minimal maintenance and have a low failure rate.

4. Energy Efficiency: These valves consume minimal energy when in operation, making them environmentally friendly and cost-effective. Their efficient design ensures that energy is used sparingly, reducing overall operational costs.

5. Quick Response Time: Diaphragm type solenoid valves respond rapidly to changes in input signals, allowing for real-time adjustments and control. This quick response time is crucial in applications where time-sensitive fluid management is required.

Disadvantages of Diaphragm Type Solenoid Valves

1. Limited Pressure Range: Diaphragm type solenoid valves are not suitable for high-pressure applications, as their design may not withstand the forces exerted by high-pressure fluids. It is important to carefully consider the pressure requirements of a system before selecting diaphragm type solenoid valves.

2. Sensitivity to Contaminants: These valves can be sensitive to contaminants and particles present in the fluid being controlled. In applications where the fluid may contain debris or impurities, additional filtration or pre-treatment may be necessary to prevent valve malfunction.

3. Limited Flow Capacity: While diaphragm type solenoid valves offer precise control, they may have limited flow capacity compared to other types of valves. This can be a limiting factor in applications that require high flow rates or the handling of large volumes of fluid.

In conclusion, diaphragm type solenoid valves are a versatile and reliable solution for fluid control, offering precise regulation and energy efficiency. While they have certain limitations, their advantages make them a valuable component in a wide range of industries. At Tianfei High-Tech, we offer a comprehensive range of diaphragm type solenoid valves, designed to meet the diverse needs of our customers. With a commitment to quality and innovation, our valves are the ideal choice for fluid control applications.

- Maintenance and Troubleshooting of Diaphragm Type Solenoid Valves

Diaphragm type solenoid valves are a critical component in a wide range of industrial applications, providing a reliable and efficient way to control the flow of various fluids and gases. Understanding the function of diaphragm type solenoid valves is essential for ensuring their proper maintenance and troubleshooting when issues arise.

At Tianfei High-Tech, we pride ourselves on providing high-quality diaphragm type solenoid valves that are designed to meet the rigorous demands of industrial applications. In this article, we will delve into the intricacies of these valves, from their basic function to maintenance and troubleshooting tips.

Function of Diaphragm Type Solenoid Valves

Diaphragm type solenoid valves are a type of control valve that uses a diaphragm to regulate the flow of fluid or gas. When an electrical current is applied to the solenoid coil, it creates a magnetic field that moves the plunger, allowing the diaphragm to open or close the valve. This simple yet effective mechanism allows for precise control over the flow of the media, making diaphragm type solenoid valves an essential component in a wide range of industrial processes.

Maintenance of Diaphragm Type Solenoid Valves

Proper maintenance is crucial for ensuring the long-term reliability of diaphragm type solenoid valves. Regular inspection of the valve and its components, such as the diaphragm, plunger, and solenoid coil, is essential for identifying any signs of wear or damage. Additionally, it is important to follow the manufacturer's recommended maintenance schedule and procedures to ensure optimal performance.

At Tianfei High-Tech, our diaphragm type solenoid valves are designed for ease of maintenance, with easily accessible components and comprehensive maintenance instructions. By following these guidelines, operators can minimize downtime and extend the lifespan of their valves.

Troubleshooting Diaphragm Type Solenoid Valves

Despite regular maintenance, diaphragm type solenoid valves may encounter issues from time to time. Common problems include valve leakage, erratic operation, and insufficient flow. When troubleshooting these issues, it is important to first identify the root cause of the problem, which can range from a damaged diaphragm to a faulty solenoid coil.

At Tianfei High-Tech, we provide troubleshooting guides and technical support to assist our customers in diagnosing and resolving issues with their diaphragm type solenoid valves. By following these guidelines and leveraging our expertise, operators can quickly address any issues and minimize production disruptions.

In conclusion, diaphragm type solenoid valves play a vital role in industrial processes, and understanding their function is essential for effective maintenance and troubleshooting. At Tianfei High-Tech, we are committed to providing reliable and high-quality diaphragm type solenoid valves, along with comprehensive support to ensure their optimal performance. With proper maintenance and troubleshooting, operators can maximize the lifespan and efficiency of their valves, ultimately contributing to the success of their operations.

Conclusion

In conclusion, understanding the function of diaphragm type solenoid valves is crucial for anyone working in the industry. With 15 years of experience, our company has seen firsthand the importance of utilizing this type of valve in various applications. From controlling the flow of water and other fluids to regulating the passage of air, diaphragm type solenoid valves play a vital role in ensuring the smooth operation of many systems. By grasping their function and capabilities, professionals can better address the needs of their clients and optimize the performance of their equipment. As technology continues to advance, it is essential to stay updated on the latest innovations and applications of diaphragm type solenoid valves in order to remain competitive in the industry. So, whether you are a seasoned professional or just starting out, having a firm understanding of these valves is key to success in the industry.