Tianfei High-tech has been on the motorized ball valve factory for 25 years tf.co@tfjt.com whatsapp:+86 18920338351

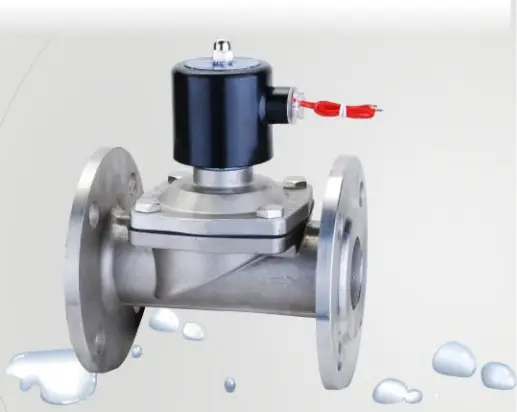

The Function And Application Of Diaphragm Solenoid Valves

Welcome to our exploration of the function and application of diaphragm solenoid valves. In this article, we will delve into the inner workings of these critical components, their uses across various industries, and their importance in maintaining efficient and reliable systems. Whether you are a seasoned engineer or someone looking to expand their knowledge in fluid control technology, this article will provide valuable insights into the benefits and applications of diaphragm solenoid valves. Join us as we uncover the pivotal role these valves play in numerous industries and the advancements they continue to drive in modern engineering.

Introduction to Diaphragm Solenoid Valves

Diaphragm solenoid valves are an essential component in many industrial and commercial applications, providing reliable and precise control of fluid flow. In this article, we will explore the function and application of these valves, and how they can benefit various industries.

Function of Diaphragm Solenoid Valves

Diaphragm solenoid valves are a type of solenoid valve that use a flexible diaphragm to control the flow of fluids. When an electrical current is applied to the solenoid, it creates a magnetic field that pulls the diaphragm open, allowing the fluid to pass through. When the current is removed, the diaphragm returns to its original position, closing off the flow of fluid.

One of the key advantages of diaphragm solenoid valves is their ability to provide precise control over the flow of fluid. This makes them ideal for applications where accurate dosing or mixing of liquids is required. Additionally, diaphragm solenoid valves are generally less susceptible to clogging and have a longer lifespan compared to other types of valves.

Applications of Diaphragm Solenoid Valves

Diaphragm solenoid valves are widely used in industries such as water treatment, chemical processing, pharmaceutical manufacturing, and food and beverage production. In the water treatment industry, these valves are used to control the flow of water and other fluids in filtration systems, desalination plants, and wastewater treatment facilities.

In the chemical processing and pharmaceutical industries, diaphragm solenoid valves are used to control the flow of various chemicals and solvents in manufacturing processes. Their precise control and resistance to corrosion make them an ideal choice for these applications. In the food and beverage industry, diaphragm solenoid valves are used to control the flow of ingredients in beverage production, as well as in bottling and packaging processes.

Tianfei High-Tech Diaphragm Solenoid Valves

At Tianfei High-Tech, we are committed to providing high-quality diaphragm solenoid valves for a wide range of industrial applications. Our diaphragm solenoid valves are designed to provide precise control and reliable performance, even in the most demanding environments.

We offer a variety of diaphragm solenoid valves, including direct-acting and servo-assisted models, to meet the specific needs of our customers. Our valves are made from high-quality materials and are designed to withstand harsh operating conditions, making them suitable for use in a variety of industries.

In conclusion, diaphragm solenoid valves play a crucial role in controlling the flow of fluids in various industrial applications. Their precise control and reliability make them an essential component in industries such as water treatment, chemical processing, pharmaceutical manufacturing, and food and beverage production. At Tianfei High-Tech, we are proud to offer high-quality diaphragm solenoid valves that meet the specific needs of our customers and provide reliable performance in demanding environments.

The Mechanism and Operation of Diaphragm Solenoid Valves

Diaphragm solenoid valves are an essential component in various industries, providing precise control of fluids and gases in a wide range of applications. In this article, we will delve into the mechanism and operation of diaphragm solenoid valves, shedding light on their function and application.

The mechanism of diaphragm solenoid valves is relatively simple yet highly effective. These valves consist of a diaphragm, a solenoid coil, and a valve body. When an electrical current is passed through the solenoid coil, it generates a magnetic field that moves an armature, which in turn opens or closes the valve. The diaphragm, typically made of a flexible material such as rubber or elastomer, acts as a barrier between the fluid or gas and the solenoid coil, ensuring proper sealing and precise control of flow.

The operation of diaphragm solenoid valves is based on the principles of electromagnetism and fluid dynamics. When the solenoid coil is energized, it attracts the armature, lifting it and allowing the diaphragm to open the valve, allowing the fluid or gas to flow through. Conversely, when the electrical current is interrupted, the magnetic field dissipates, causing the armature to return to its original position, closing the valve and stopping the flow.

Diaphragm solenoid valves are widely used in various industries, including but not limited to, industrial automation, medical equipment, water treatment, chemical processing, and HVAC systems. Thanks to their precise control, reliability, and versatility, these valves are essential for regulating the flow of liquids and gases in complex systems.

At Tianfei High-Tech, we specialize in the design and manufacturing of high-quality diaphragm solenoid valves. Our valves are engineered to meet the highest industry standards, providing exceptional performance and long-term reliability. With our extensive experience and expertise in the field, we have developed a range of diaphragm solenoid valves that cater to diverse applications and operating conditions.

As a leading provider of diaphragm solenoid valves, our commitment to innovation and excellence sets us apart in the industry. We continuously strive to enhance the design and performance of our valves, ensuring that they meet the evolving needs of our customers and the dynamic requirements of modern industrial processes.

In conclusion, diaphragm solenoid valves play a crucial role in the precise control of fluids and gases in a wide range of applications. Understanding the mechanism and operation of these valves is essential for ensuring their proper function and optimal performance. At Tianfei High-Tech, we are dedicated to providing high-quality diaphragm solenoid valves that meet the most demanding requirements, delivering reliable and efficient solutions for our customers.

Industrial and Commercial Applications of Diaphragm Solenoid Valves

Diaphragm solenoid valves are widely used in industrial and commercial applications due to their reliability and versatility. These valves are an essential component in various systems and processes, ensuring the efficient and precise control of fluid flow. In this article, we will explore the function and application of diaphragm solenoid valves, with a focus on their use in different industries and commercial settings.

At Tianfei High-Tech, we understand the significance of diaphragm solenoid valves in modern engineering and manufacturing. As a leading manufacturer of industrial valves, we are committed to providing high-quality products that meet the needs of our customers in diverse sectors. With a strong emphasis on innovation and performance, our diaphragm solenoid valves are designed to deliver exceptional reliability and functionality in a wide range of applications.

The Function of Diaphragm Solenoid Valves

Diaphragm solenoid valves are a type of solenoid valve that uses a flexible diaphragm to control the flow of fluid. The operation of these valves is based on the principle of electromagnetism, where an electrical current is used to generate a magnetic field, which in turn actuates the valve. When the solenoid is energized, the magnetic force pulls the diaphragm into the valve body, allowing the fluid to flow through the orifice. Conversely, when the solenoid is de-energized, the diaphragm is relaxed, and the valve is closed, stopping the flow of fluid.

One of the key advantages of diaphragm solenoid valves is their ability to provide a tight seal, preventing leakage and ensuring precise control of the fluid flow. The diaphragm also acts as a barrier between the fluid and the solenoid, making these valves suitable for use with a wide range of media, including corrosive and abrasive substances.

Industrial Applications of Diaphragm Solenoid Valves

In industrial settings, diaphragm solenoid valves are used in a variety of applications, including process control, fluid handling, and automation. These valves are commonly employed in industries such as chemical processing, water treatment, oil and gas, and food and beverage production. They are suitable for controlling the flow of liquids, gases, and steam, making them a versatile solution for many industrial processes.

Tianfei High-Tech offers a range of diaphragm solenoid valves that are specifically designed for industrial applications. Our valves are engineered to withstand harsh operating conditions and provide reliable performance in demanding environments. With features such as corrosion-resistant materials, high pressure and temperature ratings, and low power consumption, our valves are well-suited for use in a wide variety of industrial processes.

Commercial Applications of Diaphragm Solenoid Valves

In addition to industrial applications, diaphragm solenoid valves are also commonly used in commercial settings. These valves are utilized in HVAC systems, irrigation systems, commercial kitchens, and vending machines, among other applications. They play a crucial role in controlling the flow of water, air, and other fluids in commercial buildings and facilities, contributing to the efficient operation of these systems.

Tianfei High-Tech provides a comprehensive selection of diaphragm solenoid valves that are specifically designed for commercial use. Our valves are engineered to deliver dependable performance and energy-efficient operation, making them an ideal choice for a wide range of commercial applications. With features such as compact design, low noise operation, and rapid response times, our valves are well-suited for use in various commercial systems and equipment.

In conclusion, diaphragm solenoid valves are an integral component in many industrial and commercial applications, providing precise control of fluid flow and reliable performance. Tianfei High-Tech is dedicated to delivering high-quality diaphragm solenoid valves that meet the demands of our customers in diverse industries. With our commitment to innovation and excellence, we strive to be a trusted partner for all your valve needs.

Advantages and Limitations of Diaphragm Solenoid Valves

Diaphragm solenoid valves are crucial components in a wide range of industries, playing a vital role in controlling the flow of fluids and gases. This article will delve into the advantages and limitations of diaphragm solenoid valves, providing a comprehensive overview of their function and application.

Advantages of Diaphragm Solenoid Valves:

1. Reliability: One of the key advantages of diaphragm solenoid valves is their exceptional reliability. The diaphragm design ensures a tight seal, preventing leaks and ensuring the efficient control of fluid and gas flow.

2. Versatility: These valves are highly versatile and can be used in a variety of applications, including water treatment, chemical processing, pharmaceuticals, and more. Their ability to handle a wide range of fluids and gases makes them a valuable asset in many industries.

3. Low Maintenance: Diaphragm solenoid valves are relatively low maintenance, requiring minimal attention to keep them functioning optimally. This makes them a cost-effective option for businesses looking to minimize downtime and maintenance costs.

4. Precise Control: These valves offer precise control over the flow of fluids and gases, allowing for accurate regulation of pressure and flow rates. This level of control is essential in many industrial processes, ensuring consistent and reliable results.

5. Energy Efficiency: Diaphragm solenoid valves are designed to be energy efficient, helping businesses reduce their overall energy consumption and operating costs.

Limitations of Diaphragm Solenoid Valves:

1. Limited Pressure Range: One limitation of diaphragm solenoid valves is their limited pressure range. While they are suitable for low to medium pressure applications, they may not be suitable for high-pressure environments.

2. Sensitivity to Contaminants: Diaphragm solenoid valves can be sensitive to contaminants in the fluid or gas being controlled, which can affect their performance over time. Regular maintenance and cleaning are necessary to ensure their continued functionality.

3. Size Limitations: These valves may have size limitations, making them unsuitable for larger flow applications. Businesses requiring larger flow rates may need to consider alternative valve options.

Application of Diaphragm Solenoid Valves:

Tianfei High-Tech offers a range of diaphragm solenoid valves designed to meet the specific needs of various industries. Our valves are suitable for use in water treatment systems, chemical processing plants, pharmaceutical manufacturing, and more. The versatility and reliability of our diaphragm solenoid valves make them an ideal choice for businesses looking for precise control over fluid and gas flow.

In conclusion, diaphragm solsoloid valves are a valuable asset in a wide range of industrial applications, offering reliability, versatility, and precise control. While they may have limitations, their advantages make them a popular choice for businesses across various industries. At Tianfei High-Tech, we are committed to providing high-quality diaphragm solenoid valves that meet the needs of our customers and contribute to the efficiency and productivity of their operations.

Considerations for Selecting and Installing Diaphragm Solenoid Valves

Diaphragm solenoid valves are essential components in countless industrial applications, playing a crucial role in controlling the flow of various fluids. From the pharmaceutical industry to water treatment plants, these valves are relied upon for their precision and reliability. In this article, we will delve into the function and application of diaphragm solenoid valves, as well as provide considerations for selecting and installing them.

Function and Application

Diaphragm solenoid valves are a type of solenoid valve that use a flexible diaphragm to regulate the flow of liquids and gases. When an electrical current is applied to the solenoid, it generates a magnetic field that pulls the diaphragm into the valve seat, allowing the fluid to flow through. This mechanism provides precise control over the flow rate and pressure of the fluid, making diaphragm solenoid valves ideal for applications where accuracy is paramount.

These valves are commonly used in a wide range of industries, including medical and pharmaceutical, food and beverage, water and waste management, and chemical processing. Their ability to handle corrosive and aggressive fluids, as well as their high reliability and long service life, make diaphragm solenoid valves a popular choice for these applications.

Considerations for Selecting Diaphragm Solenoid Valves

When selecting diaphragm solenoid valves for a specific application, there are several key considerations to keep in mind. Firstly, it is important to consider the type of fluid being controlled, as well as its temperature, pressure, and chemical composition. Different materials and designs are available to suit various fluid types, so it is essential to ensure that the valve is compatible with the specific requirements of the application.

Additionally, factors such as the flow rate, response time, and pressure drop should be taken into account when selecting a diaphragm solenoid valve. It is crucial to choose a valve that can provide the required flow rate and response time while minimizing pressure drop to ensure efficient operation.

Installing Diaphragm Solenoid Valves

Proper installation is crucial to the performance and longevity of diaphragm solenoid valves. It is important to carefully follow the manufacturer's installation guidelines and ensure that the valve is installed in the correct orientation and position. This includes considering factors such as the direction of flow, the presence of any obstructions or contaminants, and the accessibility for maintenance and repair.

Furthermore, it is essential to ensure that the valve is properly connected to the electrical supply and that the voltage and current requirements are met. Proper electrical connections and grounding are crucial to prevent malfunctions and ensure the safe operation of the valve.

In conclusion, diaphragm solenoid valves are indispensable components in a wide range of industrial applications, providing precise control over the flow of fluids. When selecting and installing these valves, it is essential to consider factors such as the type of fluid, flow rate, and operating conditions to ensure optimal performance. By carefully considering these factors and following proper installation procedures, diaphragm solenoid valves can provide reliable and efficient operation for many years to come.

As a leading provider of high-quality diaphragm solenoid valves, Tianfei High-Tech is committed to delivering superior performance and reliability. Our extensive range of diaphragm solenoid valves is designed to meet the diverse needs of our customers, providing precise control and long-lasting operation. With a focus on quality, innovation, and customer satisfaction, Tianfei High-Tech is the trusted choice for diaphragm solenoid valves.

Conclusion

In conclusion, diaphragm solenoid valves play a crucial role in controlling the flow of various fluids and gases in a wide range of industries. From their ability to handle corrosive and high-purity fluids to their use in medical equipment and industrial automation, these valves have proven to be versatile and essential components. With 15 years of experience in the industry, our company has a deep understanding of the function and application of diaphragm solenoid valves, and we are committed to providing high-quality products and exceptional customer service to meet the diverse needs of our clients. As technology continues to advance, we look forward to further developments in diaphragm solenoid valves and their continued impact on numerous industries.